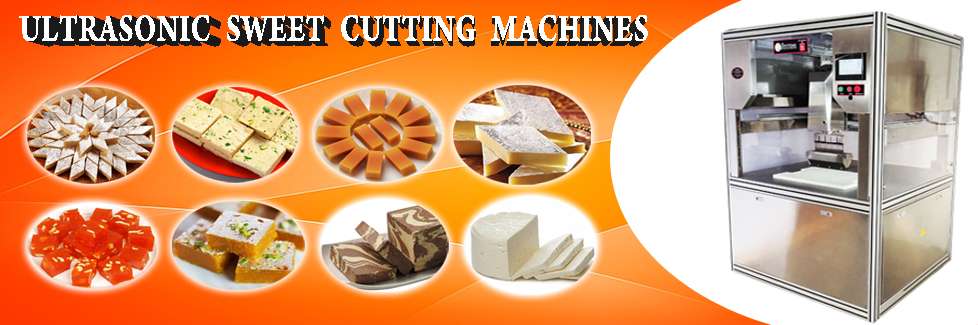

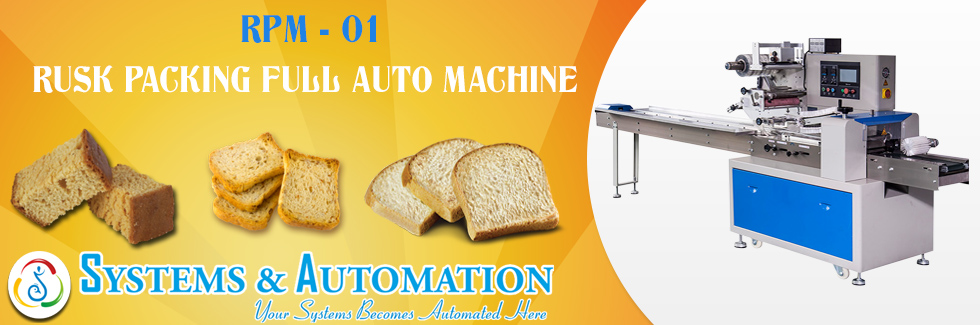

Products

We provide best products such as cake cutting machines, rusk packing machines,Sweet cutting machines, Cookies depository etc.We ensure that our manufactured machines are stringently quality tested as per international quality standards. To examine the whole process and products, we adhere to a strict quality norms. Thus, our products are highly appreciated by our clients for their superior features such as trouble free performance, low maintenance, easy installation and durability.